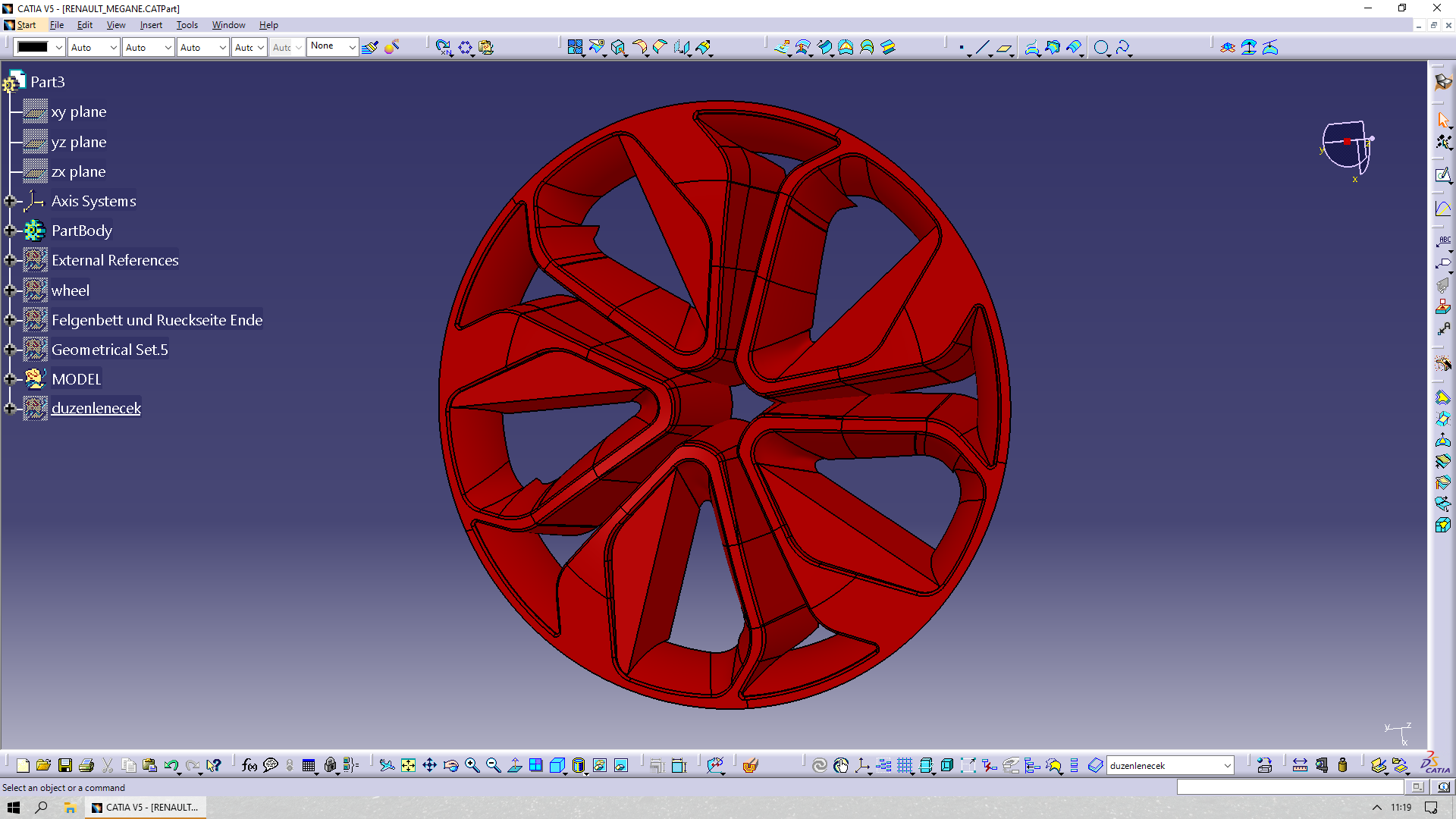

DESIGN

The modeling, mold design and production of our wheels are carried out by our experienced team in our factory. The desired model is designed by our engineers in 3D with professional software. The mold is produced by our technical staff in our factory. The mold is made in extra-precision CNC machining centers and is meticulously assembled.

QUALITY

The made models are subjected to mechanical durability tests such as impact, radial and bend fatigue, corrosion before being put into mass production. Models that have passed the tests performed after the trial casting receive mass production approval.

Due to our understanding of quality, we carry out checks at every stage of production. These controls are returned to the Çağlas factory as low loss, high quality; and to the Çağlas brand as high customer satisfaction.

FOUNDRY

Original aluminum ingots of the highest quality are used in our factory, which produces them by low pressure casting technique. The mineral, which is made liquid in the smelting quarry, is subjected to degassing. The dumped products undergo X-Ray control. After other measurements and quality controls are made, they are taken to the area where they will be processed.

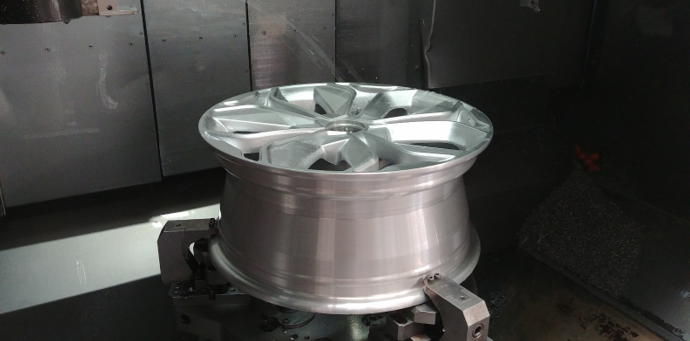

MACHINING

In principle, Caglas produces wheels that meet both high safety requirements and have no balance, secretion and wobble problems. It uses state-of-the-art CNCs to achieve flawless surfaces. Whether it is mounting surfaces or wheel and valve holes, every operation is performed with high precision. Each wheel undergoes a sealing test. It is delivered to the paint shop after the approval of the quality engineer.

PAINT

No matter how important the “inner beauty” of a wheel is, we are aware that it is the outer beauty that sells it. For this reason, we use proven brands in the wheel sector as equipment and materials in our paint shop. Here we see the secret of providing strength not only in the image, but also beyond the industry standards. We do not compromise on quality when using customer-oriented colors. Each wheel processed in our pretreatment, powder coating and wet painting lines is examined by master eyes before entering the package. Packing is done in the same way that the wheels can go on overseas trips.